What is Acid-Free Card and Why Acid-Free Materials Matter In Archival Displays

Mountame InvisaWallet™ Inserts are made from the finest grade acid-free cotton-based material to protect your collections. Furthermore, most of the traditional media that go into our InvisaWallet™ are paper products such as trading cards and postage memorabilia.

To understand deterioration in the paper you have to understand a bit of chemistry and biology, but it is worth it to see why we value our InvisaWallet™ inserts so highly. The rate and severity of the deterioration of a collection is the combined result of both internal and external factors. As such, the two greatest of these are the original materials used in the manufacturing of the paper and the conditions in which the collection is stored.

Papermaking originated around 3,000 BC when paper products were originally made from papyrus reeds. Across the world, wood has taken precedence alongside a wide range of other plant materials such as jute, bamboo, hemp and cotton. Paper has even been known to be made from animal products such as the mulberry silkworm’s silk and sheepskin. While we can only do so much with the original composition of the archivable items, the storage solution means a lot to us. Therefore, a quick review of our material selection will give you a greater understanding of why we have chosen our materials.

Understanding Plant Structures

The building blocks of paper are the best place to start when looking at why it deteriorates over time. There are two main components in paper that you need to be concerned about with regards to acid degradation, these are as follows: cellulose and lignin. See how our Mountame InvisaWallet ™ inserts counteract, protect and extend the life of your collections.

Cellulose

Paper is made primarily of a repeating chain of glucose molecules called cellulose which is derived from various plant cell walls. Cellulose is the most ubiquitous and abundant organic polymer made by living things on Earth, and the most important skeletal like component in plants keeping them rigid. The homopolymer is a long stiff ribbon-like fibre characterized by its moisture retention, non-toxicity, biodegradability and versatile semicrystalline fibres that have high tensile and compressive strength.

Lignin

Lignin, another organic polymer is the second most abundant following cellulose and is essentially the glue that holds the fibres of a tree together. It is very strong and rigid giving trees like redwoods their great height. Unlike its counterpart pectin, another common cellulose binding agent found in plants, the lignin plays a larger part in the final paper makeup. However, when considering lignin as a material used in paper derivatives it has a negative impact due to its acidic effect overtime which quickens its degradation, shorting the longevity of the paper.

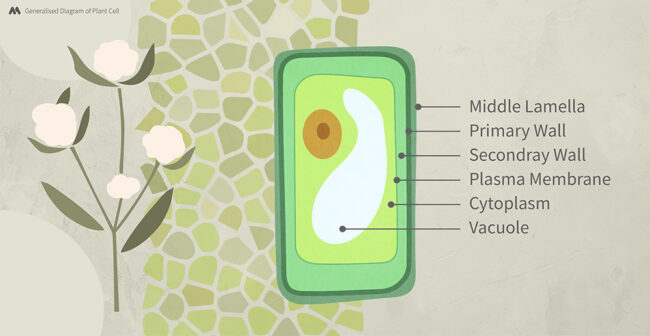

The Plant Cell Wall Structure

Lignin, pectin and cellulose together build up parts of the plant’s cell wall. This wall has 3 main layers: The Middle Lamella, the Primary Wall and a Secondary Wall encasing the Plasma Membrane and internal cell structure.

The top layer, named the Middle Lamella, connects neighbouring cells together to form a strong structure and is also very flexible. Next to this, the Primary Wall is composed of cellulose in the form of microfibrils. They naturally form a mesh in the cell wall, layer after layer, intermixed with pectin. The 3rd and final layer is the Secondary Wall and is extremely rigid, composed of cellulose fibres again, but this time with added lignin, making it very hard and giving plants their strength and rigidity.

Different plants and sections of plants have different amounts of lignin to vary their flexibility and strength. The cellulose content of cotton fibre is ~90%, papyrus 55–70%, wood 40–50%, and that of dried hemp is ~57%.

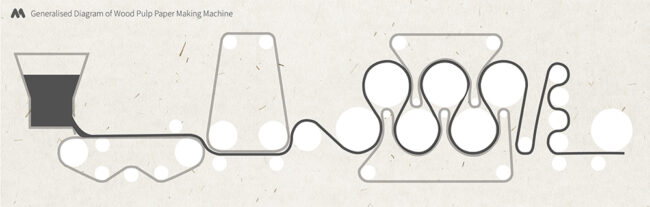

The readily available wood pulp, which thus made the printed word available to the general public took centre stage in the advent of the steam-driven paper making machine the “Fourdrinier”. This machine in the 19th century made many longer-lasting materials such as cotton redundant and was left to more niche paper mills.

The effects of acid on paper and cellulose structures

Acid degradation is caused by compounds repeatedly cutting the glucose chains found within paper into shorter lengths. Some of this can be caused by the following:

- Environmental acids such as air pollution (mainly sulfur and nitrogen oxides) when moisture is present.

- From within the paper itself in a form such as ageing lignin.

- Adatives such as glossing agents or optical brightening agents (OBAs)

- From the manufacturing process (such as bleach from the refining process).

- All types of light (such as visible and UV) and other external factors.

This shorting of the glucose chains, known as a hydrochloric acid hydrolysis reaction, produces even more acids (such as hydrochloric, formic, acetic, lactic, and oxalic acids), further feeding degradation of the fibre. Lignin in paper over time breaks down cyclically as the process produces further acid. Removing as much of this lignin as possible is key to a longer-lasting paper that will not contaminate a surrounding collection or degrade itself over time.

If an acidic product, such as a non-based (another word for non-buffered or non-alkali) hobbyist card, touches a collection made of paper, the acid can transfer. This causes permanent damage and decay making an InvisaWallet™ insert the ideal protective barrier for keeping a collection safe.

Paper processing

Mechanical Pulping

Mechanical pulping produces wood pulp paper with the shortest fibre length and thus the weakest and also does not remove lignin from the wood, which promotes acid hydrolysis. Newspapers, for example, are printed on mechanically pulped paper and thus last a very short time – degrading very fast.

Chemical Pulping

Chemical wood pulping removes lignin and does not cut up the cellulose chains as thoroughly as mechanical pulping, yielding a comparatively stronger paper. This, however, is still not as durable as ‘rag’ paper, a paper made from cotton fibre almost free from lignin due to its cell wall makeup.

Cylinder Moulding

Mountame’s InvisaWallet™ 100% cotton insert is created with the process of a more traditional cylinder mould thus retaining its very long fibres and has a much higher strength. This process does not include lignin extraction as its biological makeup only includes a trace amount. Subsequently, this means minimal chemicals are used in the cylinder moulding of cotton, reducing the chance of foreign contaminants.

What is Acid-Free Card and paper?

Acid-free pulp boards such as paper and card are products produced with a pH greater than 7. The pH scale is the standard for measurement of acidity and alkalinity and ranges from 1 to 14 with each number representing a ten-fold increase; pH neutral is 7.

Many paper and card products in modern times specify that they are acid-free, lignin-free or both and the majority of commercial printing papers today are actually acid-free to some standard. The main problem is ensuring that ‘acid-free’ standard over time as unfortunately as the lignin breaks down over time the pH of the paper changes. This means that specifically pH neutral ‘acid-free’ papers are increasingly acidic as they age only if they are not documented as lignin-free and thus increasingly degrade within, or are damaging to, your collection.

It is also worth noting that besides acid hydrolysis, most paper is susceptible to photolytic light damage and oxidative degradation; although the role of this is limited compared with acid hydrolysis, except in the presence of specific nitrogen oxide pollutants.

What can I do to prevent my collections from acidic damage?

Generally speaking, good quality papers, stored in cooler temperatures and 30-40% relative humidity can last a long time – hundreds of years. However, as we are finding, our beloved collections do not have the greatest quality when it comes to their paper. With acid-based degradation being the most actionable reaction, we can neutralize the acids proactively with an alkalizing agent such as the calcium found in our Inserts.

If the archive item undergoes deacidification treatment via based (alkali) treatment while the paper still has significant measurable strength, and the treated items are then stored under proper conditions, these once-acidic items are projected to remain in a usable condition for several centuries, rather than becoming brittle and unstable in a lifetime extending the longevity of your collections.

There is some wiggle room in the definition of conservation-grade vs archival-grade but they are usually defined as such:

- Conservation-grade: acid-free and buffered paper but made from wood-based pulp (‘high alpha’ wood pulp is considered ~93% cellulose).

- Archival-grade & Museum-grade: a cotton rag paper made from cotton pulp thus generally acid-free (Cotton paper is ~100% cellulose).

To be clear, our Mountame InvisaWallet™ inserts are preservation grade: acid-free & buffered paper made from 100% cotton pulp and complies with ISO 9706 requirements, the standard for identifying paper that, according to the present state of knowledge, has a high degree of permanence and is likely to undergo little or no change in properties. Literally, the best you can get.